The advantages of TPU film for lumbar support airbag membrane mainly include its excellent physical properties, durability and comfort.

TPU film has high elasticity and wear resistance, which makes it perform well in complex and changeable use environments. TPU combines the advantages of rubber and plastic, has both the elasticity of rubber and the processing performance of plastic, and can maintain stable performance during long-term use

In addition, the durability and anti-aging properties of TPU film are also excellent, and it can resist the erosion of ultraviolet rays and chemical reagents, ensuring the long-term use of the airbag membrane

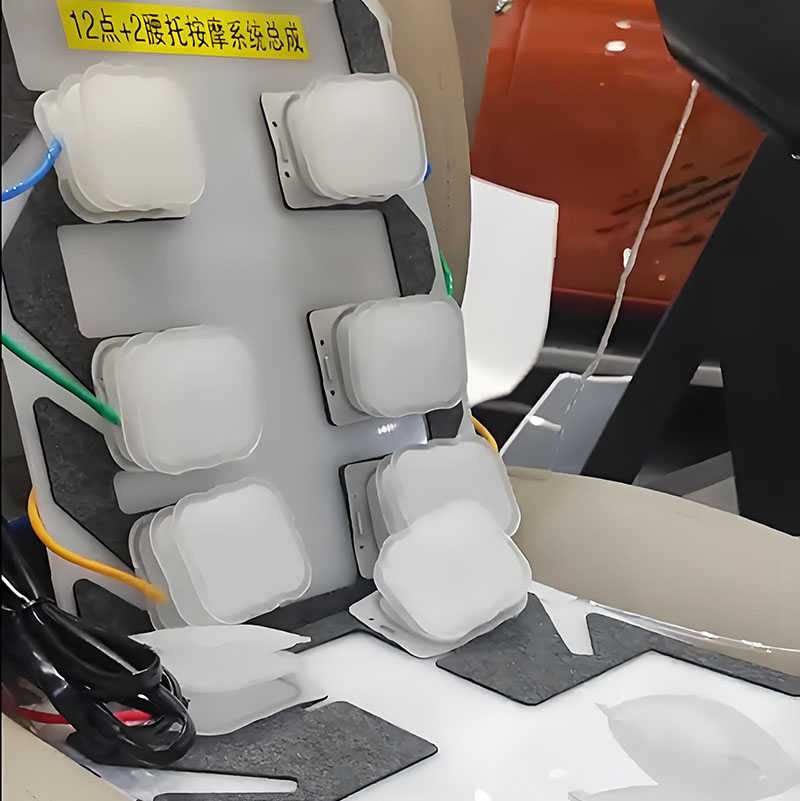

In specific applications, these characteristics of TPU film enable the lumbar support airbag membrane to provide excellent support performance and massage effect. The lumbar support airbag membrane can simulate manual massage through built-in massage technology, promote blood circulation, reduce muscle tension, and thus improve the body's comfort